Makina Odzaza Mafuta a Digital Weight Edible Odzaza Mafuta

Kufotokozera

Kufotokozera

Kudzaza zinthu zamafuta, kuphatikiza mafuta odyedwa ndi mafuta akumafakitale.Mafuta odyetserako ndiwo msika wazachuma cha dziko, ndi chimodzi mwazakudya zazikulu pamoyo wathu watsiku ndi tsiku, monga mafuta a mtedza, mafuta a kanjedza, mafuta osakanikirana ndi zina zotero.Mafuta a mafakitale ndi mafuta opaka mafuta, pamlingo waukulu wa makina opanga mafakitale masiku ano, mitundu yonse ya zipangizo zamakina sizingagwire ntchito popanda mafuta, ntchito zambirimbiri.

Kudzazidwa kwa zinthu zamafuta kumafuna kudzazidwa kwakukulu komanso mikhalidwe yaukhondo, yomwe ndiyosavuta kumamatira pamwamba pazigawo ndikuyambitsa kudontha.Kuti athetse mavutowa, makina odzazitsa mafuta a GEM samangotsimikizira zofunikira zodzaza, komanso amakwaniritsa zovuta zotulutsa mosavuta.

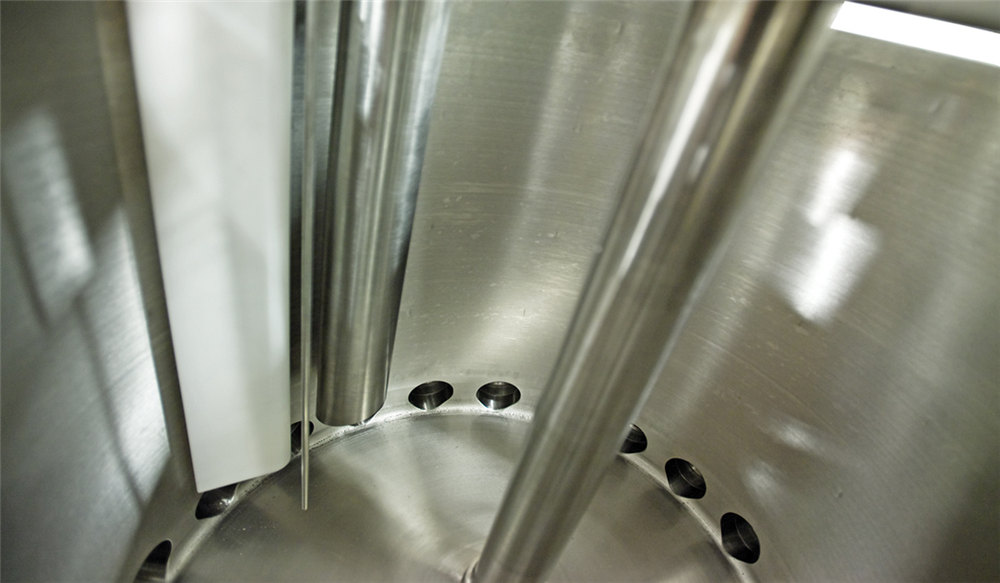

Chifukwa chakuchulukirachulukira kwazinthu zamafuta, kugwiritsa ntchito mavavu amakina wamba kumayambitsa kutsekeka kwa chitoliro chobwerera, motero makina odzazira mafuta nthawi zambiri amatenga njira yodzaza ndi plunger.Mfundo ya plunger yochulukira kudzaza njira ndikuti zinthu zomwe zili mu silinda yoyezera, silinda yodzaza, zodzaza botolo zotengera zitatu zimasinthasintha, zimayenda.Thupi la valve ndi lofanana ndi valavu yanjira zitatu.Vavu ikatsekedwa, silinda ndi silinda zimalumikizidwa, ndipo zinthuzo zimayamwa mu silinda ndi pisitoni.Kugunda kwa pistoni kumatsimikizira kuchuluka kwa zinthu zomwe zimayamwa, motero zimazindikira kuchuluka kwa zinthu zomwe zikudzazidwa.Vavu ikatsegulidwa, silinda ndi botolo zimalumikizidwa, ndipo zinthu zomwe zimayamwa mu silinda zimakanikizidwa mu botolo kuti amalize kudzaza kochulukira.Popeza mphamvu yodzaza imatha kusinthidwa posintha pisitoni, ndikosavuta kudzaza mabotolo amitundu yosiyanasiyana.Kuphatikiza apo, gawo lomwe limayang'anira pisitoni limatha kusinthidwa ndi servo drive, zomwe zimapangitsa kudzaza kolondola komanso kuthekera kosavuta.

Kupatula kudzaza kwa plunger, makina ambiri odzaza mafuta amagwiritsa ntchito ukadaulo wodzaza sikelo.Pambuyo kulemera kopanda kanthu kwa chidebe kutsimikiziridwa, valavu yodzaza imatsegulidwa pamene botolo likupezeka.Panthawi yodzaza, sensa yoyezera imazindikira kuchuluka kwa mankhwala omwe amalowetsedwa.Pamene kulemera kofunikira kukufika, valve imatseka nthawi yomweyo.Pambuyo popuma pang'ono, yang'ananinso kulemera kwake.Asanafike pa gudumu la botolo, valavu imakwezedwanso kuti botolo lichoke pamakina bwino.Njira yodzaza iyi imatha kusinthidwa ndi ntchito ya CIP yokhayokha, kuyeretsa kapu yabodza kumangodzikweza, CIP sifunikira ntchito yamanja.

Mawonekedwe Aukadaulo

1. Kudzaza kozolowereka pogwiritsa ntchito kudzaza kwa plunger, kudzaza kulondola ndikokwera, kosavuta kusintha.Valavu yodzaza ndi magetsi yoyezera / electromagnetic flowmeter imagwiritsidwa ntchito pazinthu zomwe zimafunikira kwambiri.Ziribe kanthu kuti valavu yodzaza yamtundu wanji ingalepheretse kudontha kwa valve orifice.

2. Siemens control system imatengedwa, yokhala ndi mphamvu yodzilamulira yokha, mbali zonse za ntchitoyi zimagwira ntchito bwino, palibe ntchito yomwe imafunika mutangoyamba (mwachitsanzo: kudzaza liwiro kumatsatira liwiro la mzere wonse, kuzindikira kwamadzimadzi, kulamulira kwamadzimadzi. , makina opangira mafuta, makina otumizira botolo)

3. The makina kufala utenga modular mapangidwe, pafupipafupi kutembenuka stepless liwiro malamulo, osiyanasiyana liwiro malamulo.Galimotoyo ili ndi chipangizo chodzipangira mafuta, chomwe chimatha kupereka mafuta kumalo aliwonse opaka mafuta malinga ndi nthawi komanso kuchuluka kwake, kuthirira kokwanira, kuchita bwino kwambiri, phokoso lochepa komanso moyo wautali wautumiki.

4. Kutalika kwa zinthu zomwe zili mu silinda yodzaza zimazindikiridwa ndi kafukufuku wamagetsi, ndipo PLC yotseka-loop PID control imatsimikizira kuti madzi amadzimadzi okhazikika komanso kudzazidwa kodalirika.

5. Malinga ndi zofunikira za zinthu zosiyanasiyana, njira yodzaza ndi mtundu wosindikiza ukhoza kufanana ndi kufuna.Njira zosiyanasiyana zosindikizira zilipo (mwachitsanzo, chithokomiro cha pulasitiki, kapu ya ulusi wa pulasitiki, etc.)

6. Njira yakuthupi ikhoza kutsukidwa CIP kwathunthu, ndipo benchi yogwirira ntchito ndi gawo lolumikizana la botolo likhoza kutsukidwa mwachindunji, lomwe limakwaniritsa zofunikira zaukhondo zodzaza;Itha kugwiritsidwa ntchito molingana ndi kufunikira kwa tebulo lopendekeka lambali imodzi;Makapu abodza a CIP amapezekanso.

7. Palibe kulumikizana pakati pa botolo ndi valavu yodzaza panthawi yodzaza kuti mupewe kuipitsidwa.

Kapangidwe

Parameter

| Ayi. | Model Series | Material Viscosity range CPS | mphamvu | Okonzeka ndi mpweya | Zokhala ndi gwero lamagetsi | Kutalika kwa mzere

| oyenera mtundu wa botolo |

| 01 | JH-OF-6 | 0-200 | 3kw pa | 5-6 pa | 380V | 1000 ± 50mm | Zosinthidwa malinga ndi zosowa za makasitomala

|

| 02 | JH-OF-8 | 0-200 | 3kw pa | 5-6 pa | 380V | 1000 ± 50mm | |

| 03 | JH-OF-10 | 0-200 | 3.5KW | 5-6 pa | 380V | 1000 ± 50mm | |

| 04 | JH-OF-12 | 0-200 | 3.5KW | 5-6 pa | 380V | 1000 ± 50mm | |

| 05 | JH-OF-14 | 0-200 | 4.5kw | 5-6 pa | 380V | 1000 ± 50mm | |

| 06 | JH-OF-16 | 0-200 | 4.5kw | 5-6 pa | 380V | 1000 ± 50mm | |

| 07 | JH-OF-20 | 0-200 | 5kw pa | 5-6 pa | 380V | 1000 ± 50mm |