Makina Odzazitsa a Botolo la Galasi / Whiskey Liquor Filling Machine

Kufotokozera

Mizimu ndi zakumwa zoledzeretsa zomwe zimasungunuka popanda kuwira.Mizimu yowonongeka imakhala ndi mowa wambiri wambiri, kuyambira 20% mpaka 90% ABV.Kuti apange mzimu wamphamvu, zopangira monga zipatso, mbatata ndi mbewu zimagwiritsidwa ntchito mu distillation.Zakumwa zoledzeretsa zoseweredwa ndi whiskey, gin ndi vodka.Msika wazakumwa zoledzeretsa padziko lonse lapansi ukuyembekezeka kufika pafupifupi $2 thililiyoni pofika 2025, kafukufukuyu adati.Mizimu idzawerengera gawo limodzi mwa magawo atatu a msika wonse.Zowoneka, mizimu imakhala ndi gawo lalikulu pamsika.

Kukwera kwamtengo wamtengo wapatali, kutayika kwakukulu kudzabwera chifukwa cha kuyeza kokwanira kodzaza.Pofuna kupewa kutayika koteroko, makina odzazitsa mowa a GEM-TEC amatsata mosamalitsa zomwe zimafunikira pakudzaza kolondola.Ngati mankhwala ochuluka atsanuliridwa mu chidebe, makinawo amawongolera mlingo wamadzimadzi.Zogulitsa zomwe zili ndi mowa wambiri zimafunikiranso chithandizo chosaphulika pobotolo.Makina amagetsi amakina athu amatengera zinthu zomwe sizingaphulike kuti zithetse zoopsa zomwe zingachitike.Mayankho athu ndi osavuta kuyeretsa kuti zinthu zanu zikwaniritse zofunikira zonse zaukhondo.

Mfundo yogwirira ntchito yodzaza mowa womveka bwino mu chidebe chagalasi

Makina odzaza mizimu nthawi zambiri amatenga njira yodzaza vacuum.Mizimu yolowetsedwa mu botolo imamwazikana pakhoma lamkati la botolo ndi ambulera yosokoneza, ndipo mpweya wa botolo umatengedwa ndi makina otsekemera kudzera mu chitoliro chobwerera.Njira yeniyeni ndi iyi: botolo limakwezedwa mpaka pansi pa valve yodzaza ndipo valavu yodzaza imatsegulidwa.Kudzaza kumayamba.Pamene mlingo wamadzimadzi wa vinyo mu botolo ndi wapamwamba kuposa chitoliro chobwerera, valavu idzatsekedwa.Mulingo wamadzimadzi umakonzedwanso: chowonjezera chimayamwanso mu silinda yodzaza kudzera mu chubu chachifupi.Chifukwa ntchito yotsegula ndi kutseka kwa valve imayendetsedwa ndi botolo, kotero: "palibe botolo, palibe ndondomeko yodzaza".

Zachidziwikire, muzakudya za GEM-TEC zitha kugwiritsanso ntchito makina odzaza mpira woyandama wamagetsi, kudzaza kulondola ndikokwera, mwachangu.Valavu yamagetsi imagwiritsa ntchito ukadaulo woyezera nthawi yeniyeni ndi ukadaulo wowongolera, ukadaulo wowongolera wa PLC wowongolera ntchito komanso ukadaulo wowongolera kuthamanga kwamayendedwe kuti akankhire kulondola kudzaza ndi kudzaza liwiro mpaka kutalika kwatsopano.Njira yodzaza ndi yofanana ndi njira zitatu za valve.Mizimuyo imayamba kubayidwa mu mbiya yamagetsi yamagetsi.Pambuyo pofika pamlingo wokhazikitsidwa, mizimu yomwe ili mu mbiya ya metering imalowetsedwa mu botolo.

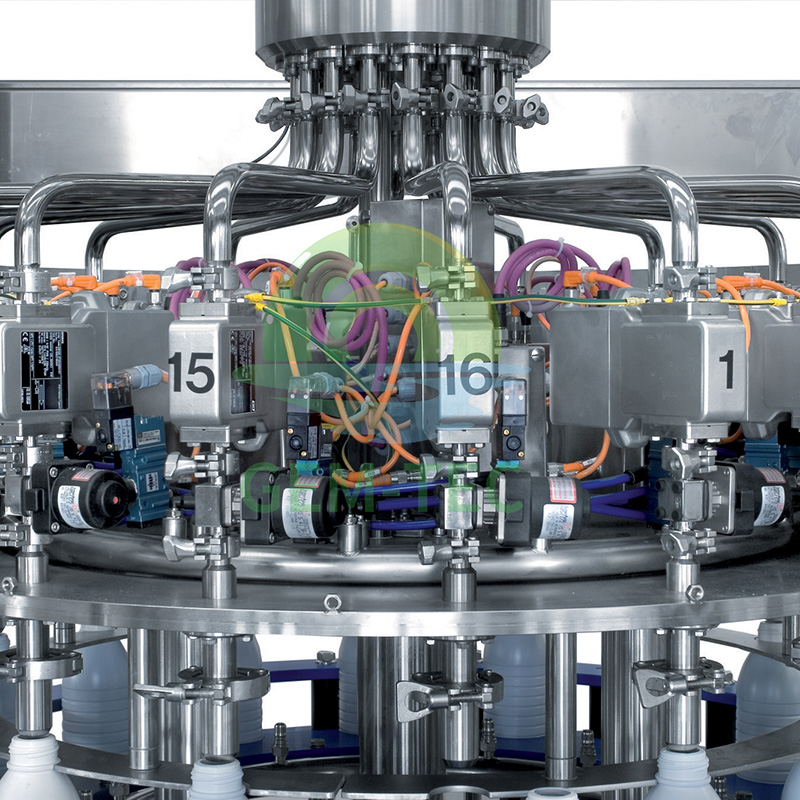

Mawonekedwe

Makhalidwe a valve yamakina

1. Onetsetsani milingo yokwanira yodzaza zolakwika ndi kutayika kwa mowa

2. Dziwani molondola kutalika kwa msinkhu wodzaza kupyolera mu kukonza vacuum ndi kutalika kwa chitoliro chobwerera

3. Vavu yodzazitsa yoyendetsedwa ndi makina, imatha +/- 4 mm yosasinthika kutalika kodzaza

4. Vavu yodzaza mwachisawawa yokhala ndi kapena popanda ntchito ya CIP

5. Chidebe chosungirako chili pamalo otsika opanda vacuum, popanda kudzaza kwa drip

6. Siemens ulamuliro dongosolo, ndi mkulu zochita zokha kulamulira luso, mbali zonse za ntchito ya opareshoni basi, palibe ntchito pambuyo poyambitsa

7. The makina kufala utenga modular mapangidwe, variable pafupipafupi stepless liwiro lamulo, osiyanasiyana liwiro.Galimotoyo ili ndi chipangizo chodzipangira mafuta, chomwe chimatha kupereka mafuta kumalo aliwonse opaka mafuta malinga ndi nthawi komanso kuchuluka kwake, kuthirira kokwanira, kuchita bwino kwambiri, phokoso lochepa komanso moyo wautali wautumiki.

8. Kutalika kwa zinthu mu silinda yodzaza kumadziwika ndi kafukufuku wamagetsi.PLC yotseka-loop PID kuwongolera kumatsimikizira mulingo wamadzimadzi okhazikika komanso kudzazidwa kodalirika.

9. Njira zosiyanasiyana zosindikizira ndizosankha (monga: kapu ya aluminiyamu, kapu ya korona, zokopa zooneka zosiyanasiyana, ndi zina zotero)

10. Njira yazinthu imatha kutsukidwa CIP kwathunthu, ndipo benchi yogwirira ntchito ndi gawo lolumikizana la botolo limatha kutsukidwa mwachindunji, lomwe limakwaniritsa zofunikira zaukhondo zodzaza;Itha kugwiritsidwa ntchito molingana ndi kufunikira kwa tebulo lopendekeka lambali imodzi;Makapu abodza a CIP amapezekanso.

Kuphatikiza pa zomwe zili pamwambapa, valve yamagetsi imakhalanso ndi izi:

● Palibe kutayika, kosavuta kusintha: botolo mu ndondomeko yodzaza popanda kukweza kayendetsedwe kake, silimakhudzana ndi thupi la valve, pafupifupi osavala ziwalo;Pamene kusintha mphamvu, inu muyenera ndikupeza kukhudza nsalu yotchinga kusintha magawo kuti stepless kusintha, ndipo mukhoza kusunga magawo a zosiyanasiyana vinyo mu dongosolo chilinganizo.Pamene kusintha vinyo, inu muyenera kuitana zosiyanasiyana pa kukhudza chophimba basi kudzaza, kwambiri kuwongolera bwino kupanga.

● Kukonzekera kwakukulu, kudalirika kwakukulu: poyerekeza ndi makina a valve opangidwa ndi makina, zida zambiri zamagetsi zimagwira nawo ntchito yodzaza, kayendetsedwe ka kayendetsedwe kake kamakhala kolondola kwambiri, kuzindikirika kwachinsinsi.

● Palibe madzi otsamwitsa, osadontha: valavu yodzaza imatenga njira yochepetsera, mowa siwosavuta kuphulika, pafupi ndi pakamwa pa botolo pamene madzi akuyenda pang'onopang'ono, mzere wamadzimadzi umakhala wabwino ndikulowetsedwa mu botolo, kuchotsa madzi. thovu, kusindikiza kumbuyo pambuyo podzaza, osadontha.

Technical Parameter

| Mtundu wa makina | fillhead | Kutalika kwa botolo | Botolo lalikulu | Kupanga bwino | Kudzaza kulondola | Kudzaza osiyanasiyana | Kupanikizika kwa mpweya |

| JH-FF18 | 18 | 100-300 | 50-100 | ≤6600(b/h) | ± 1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| JH-FF 24 | 24 | 100-300 | 50-100 | ≤9000(b/h) | ± 1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| Chithunzi cha JH-FF 36 | 36 | 100-300 | 50-100 | ≤14000(b/h) | ± 1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| Chithunzi cha JH-FF 48 | 48 | 100-300 | 50-100 | ≤18000(b/h) | ± 1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| Mtengo wa JH-FF 60 | 60 | 100-300 | 50-100 | ≤22000(b/h) | ± 1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |

| Chithunzi cha JH-FF 72 | 72 | 100-300 | 50-100 | ≤26000(b/h) | ± 1.0ml/500ml | 40-600 ml | 0.4-0.5MPa |